Big data and industry 4.0

The different notions of the digital world

Let’s start by finding out what Industry 4.0 and Big Data are.

What is Industry 4.0?

In concrete terms, what isIndustry 4.0? It comes down to the digital transformation of production and value creation processes.

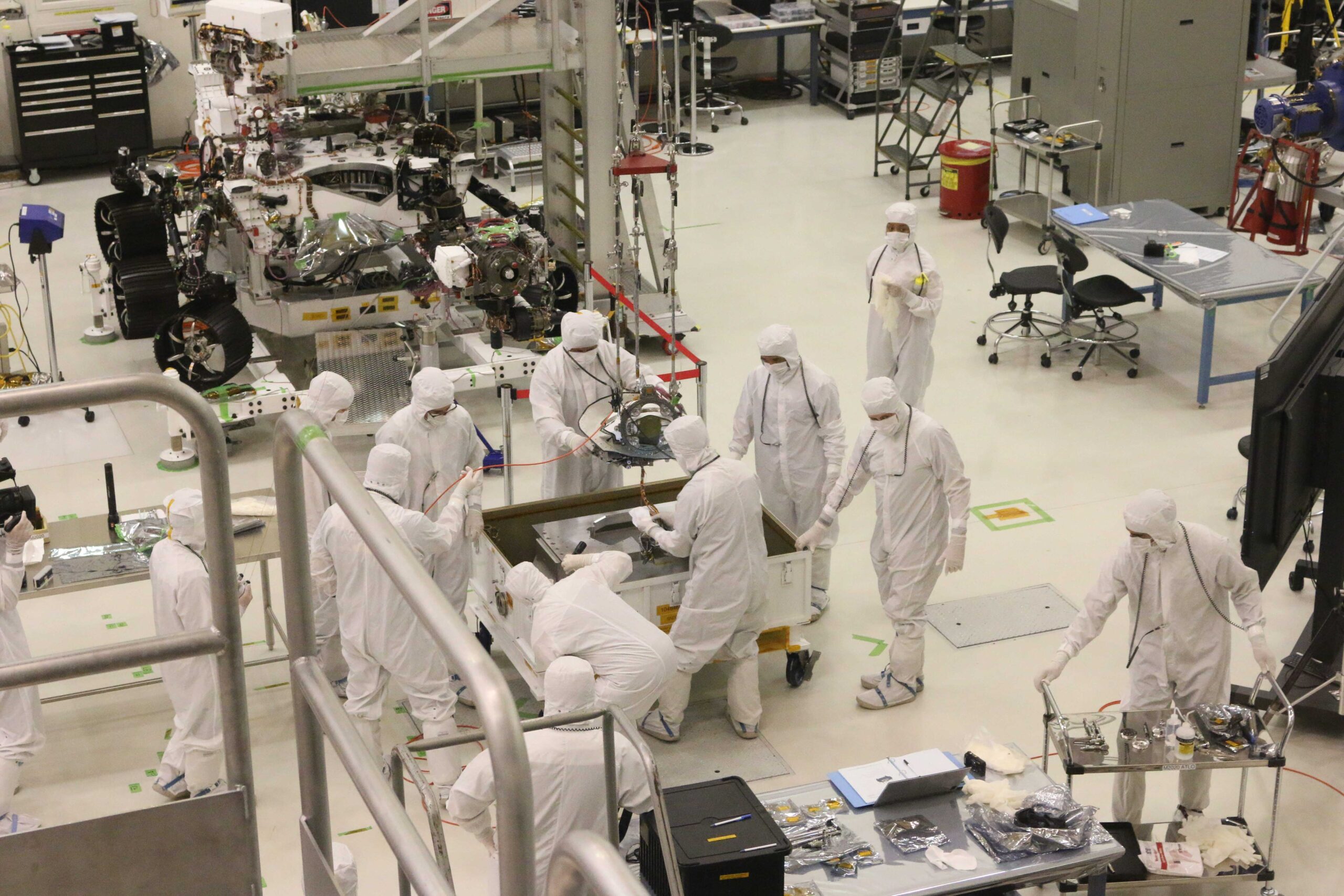

The world industryIt’s in perpetual development and this is not new! Indeed, this universe has been evolving since its creation. Butsince few years, technologies have undergone big changes. Digitalization has taken over this environment, and every day this digitalization requires companies to adapt to it.its. The 4.0 is characterized by its speed of data processing and automation. This evolution industrylle is accompanied by very precise tools, the IOT for its sensors (at all levels: temperature, GPS location, etc…), the introduction of robots to automate processes and finally the digital transformation with social networks, theintelligence artificial intelligence andand Big Data.

Its efficiency and adaptability are undeniable, Industry 4.0 is easily applied to the Supply Chain, it facilitates the needs of the players in the field, participates in the progress of the organization and management of your warehouse. These advantages apply to the entire supply chain, from the production of objects to their delivery.

With these new features, you will gain in efficiency and precision in the management of your logistics flow.

What is big data?

Big Data is a large set of data that can be explored and analyzed in order to extract exploitable information. Big Data is accessible in real time by a multitude of people.

Thanks to Big Data, data volumes are much faster. Big Data is composed and submitted to the 3V rule :

-

Volume

There is no lack of information, in fact, Big Data offers you everything you need and content of all types.content of all types.

-

Speed

Much faster than its ancient brethren, big data processes data ultra quickly. Online, it’ssome information is available in real time.

-

Variety

There is much more data available than traditionallytraditionally. This gives you a greater choice in information. This does not mean that the processing of this information is structured.

Big data & industry 4.0, how does it work?

But then how and in what way these two intelligent systems can be coupled and be a major asset for your company and your plants ?

What are the problems to which Big Data can provide answers?

The challenges linked to Big Data are numerous: managing your traceability? Setting up deliveries ? Coupling with a WMS in your factory? Digitize your processes and switch to the Wiilog solution! We are looking forward to discovering your future projects and to provide you with a tool based on an open source model, in order to best meet your economic, social and other challenges. By combining Big Data and Industry 4.0 we will be able to meet your requirements.

Big data and the new industrial era can meet your goals of improving various services :

- The management of your traceability: via very powerful tools, ensure the follow-up of all your products

- The development of your products: by anticipating all customer demands

- Innovation development in your warehouses: optimize actions thanks to collected data

- Inventory management: from receipt to delivery, control your inventory

- Maintenance of your warehouses: by enhancing the value of your stocks and alllocations

- The automation of your inventories: the data on each product is collectedat the entry in your stock so everything is automated

It will no longer be enough for you to just store data. The resulting analyses will have to be organized to allow you to exploit all this crucial information.

How to structure your activity?

Are you ready to using Industry 4.0? And do you know how to structure it? You can forget about Excel! In today’s digital age, data must be collected digitally, so as not to lose any of it.

Your use of data should be as optimized as possible, but do you even know how to master your Big Data? For this you will need:

- IntegrateWhen setting up, you need to import the data to define which ones you want to keep and how to sort them.

- Manage: you have to be able to manage the quantity of data.

- Analyze and finally it is necessary to analyze it to bring out the most important information.

But this cannot be taken for granted, we have to keep a constant eye on this powerful technology.

What is lean 4.0?

Avoid waste is the core target of lean, both in the factory and in the store. Lean has been around for about 50 years, first created in Japan by Toyota. It is now deployed in many productions. Like all services and all industrial schemes, lean has been able to adapt to many different evolutions.Today, it is in line with Industry 4.0, automating all processes to waste as little as possible. This is what all these technologies, always more efficient, are for.

Artificial intelligence

Artificial intelligence and big data have been a springboard for Industry 4.0. It is thanks to this collected and analyzed data that companies can position themselves on a market and improve their production, stock management, traceability and delivery. All your logistics can be revolutionized by these new technologies and this in an evolutionary goal for your company.