The traceability solution at SAFRAN Electronics & Defense

Aero

Our client’s problems

- Large number of employees in the production process production process

- Information entered in an Excel table that is not very practical for real-time exchanges on the progress of projects

- Lack of traceability of almost 48 hours since the reception due to lack of identification

- The percentage of losses and errors was also important during emergencies since they were reported with post-it notes!

The benefits of the Wiilog solution

-

Data analysis allows to measure the remaining workload

-

All employees can work on the application in real time

-

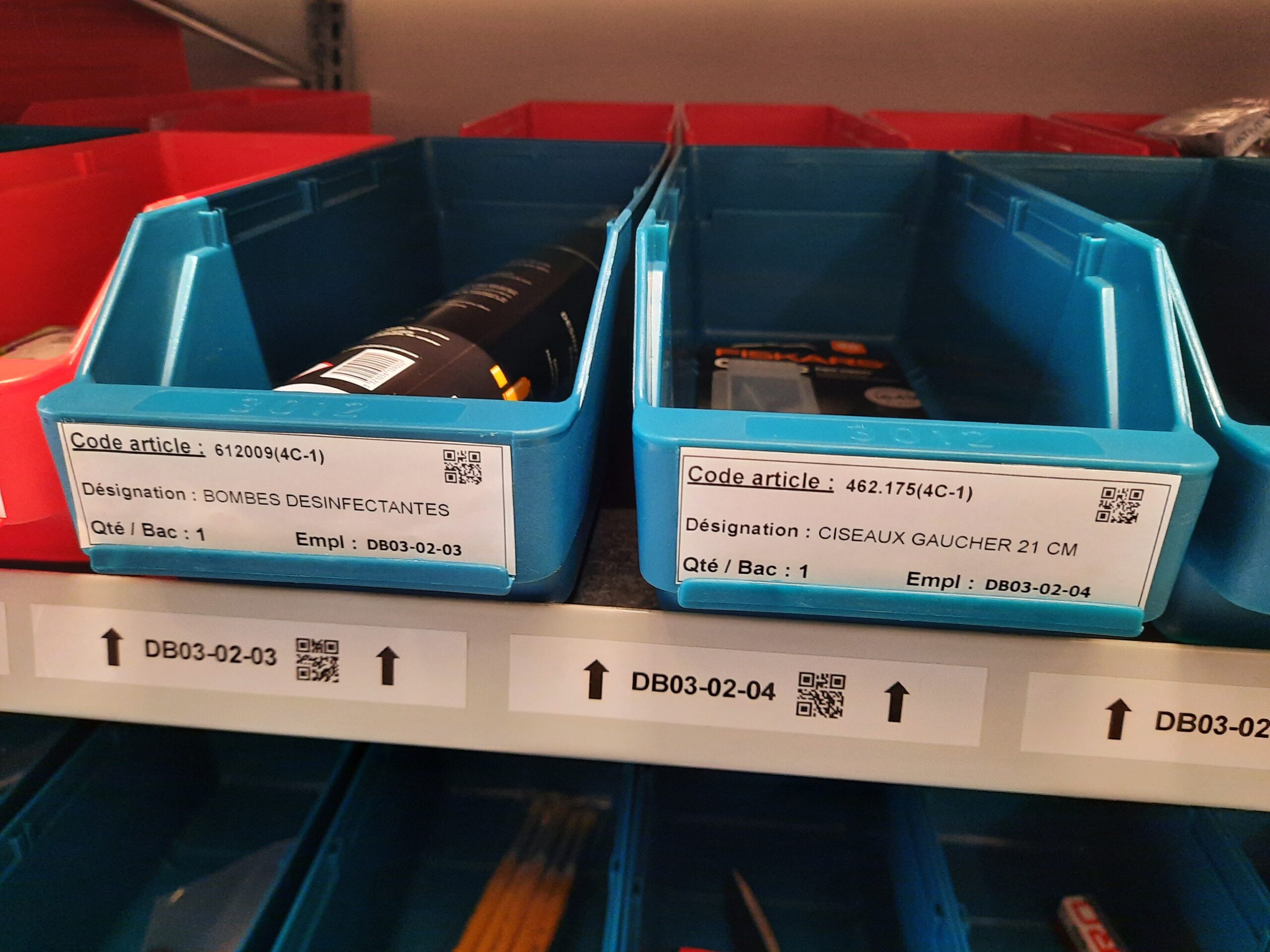

Thanks to the identification of the products, it is possible to know where it is in real time

The solutions provided

Ease of communication

- Real-time communication of up to 50 users is facilitated

- Communicating priorities through visual elements of color

Emergency management

- Emergency order number

- Notification by email to the recipient

- Indicate the urgency: red color on the arrival to be treated in urgency

We wouldn’t work without it, it’s a traceability tool (…) that improves the flow.

Stephanie Marion

Site Manager

Stephanie Marion

Site Manager

Wiilog synthesis

The SAFRAN Electronics & Defense project allowed us to develop and structure the concept of time management through a dynamic dashboard according to functional requirements. Indeed, it’s quite a challenge to meet the IT constraints!